Logistics Companies - The Facts

Wiki Article

Not known Details About Transport And Logistics Companies

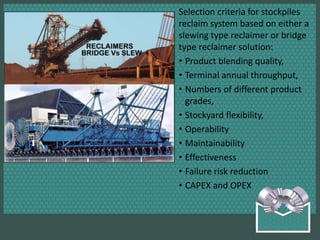

Table of ContentsThe Definitive Guide to Stockyard EquipmentsExcitement About ShippingThe Buzz on Logistics Companies ProcessThe 20-Second Trick For Logistics Companies TypesFascination About Logistics Companies Near MeThings about Shipping

An example, Telestack has lately installed a tried and tested system including the exact mixing of differing grades/ qualities of coal within a Nuclear power plant in South East Asia. In any kind of enabled plant stockyard there will be different qualities and requirements of coal which will have been sourced from various nations in numerous batch sizes.Calorific Worth Ash Web Content Sulphur Content Wetness Web content The challenge for any kind of nuclear power plant operations team is just how to properly mix the numerous grades of coal with the above differing material features to guarantee that they are sending out a regular mix to the furnace. Typically this blending had been executed by utilizing 2 x bucket wheel Stacker Reclaimers which fed onto a central conveyor which then sent the mixed coal mix to the heater.

This causes high operating prices per tonne for the process of redeeming at these lower prices. For example, a power plant may intend to blend coal of reduced calorific worth with that of a higher calorific worth. The total amount recover rate to the heating system is 1,400 tph. If using an 80% higher quality coal to 20% lower grade blend, after that the Stacker Reclaimer A is running at 1,120 tph while the Stacker Reclaimer B is just running at 280tph.

The Only Guide for Logistics Companies Transportation

The devices selected was a Telestack Mobile Track Installed Titan Truck Unloader with incorporated Receptacle Feeder with Radial & Luffing Boom. The machine was picked as a result of its superb movement as well as manoeuvrability around the narrow areas of the stockyard as well as narrow accessibility roadways between the stockpile as well as the reclaim line.The Telestack style ensures adaptability in that it can be fed by a front end loader/ excavator or vehicles. When reclaiming the equipment is fed by one, or a combination of the above, and also can be established at pre-set percent proportions with the touch of a button. The Telestack radial Titan can operate in conjunction with a Stacker Reclaimer to send out an exact blend to the heater - logistics companies transportation.

The 5-Minute Rule for Stockyard Equipments

Telestack has several tried and tested stacker and also reclaimer installments worldwide as well as remains to innovate to meet the ever-changing needs of their customers. #Moving, To, Mobile.There exists normally an inequality between the usage of the bulk materials in the plant and their arrival in the plant and hence, the bulk materials are called for to be saved. The storage of the mass products is additionally needed to deal with any interruptions in the transportation system or in the mines.

Different approaches are made use of for the keeping of the mass materials. The elements which determine the selection of storage approach for the mass products consist of (i) nature of my blog the material, (ii) quantity of products to be stored, (iii) billing and also discharging rate, and (iv) regularity of arrival and also supply to the consuming units.

Logistics Services for Dummies

Discharge of the products from the bunkers at the preferred price is accomplished by using different kinds of feeders. Stock-house containers really contains a number of standard bins organized in a raised framework for set shipment of the products to the procedure. A blast heater has such stock-house bins its stock home.

Sheds are used for short to lengthy period storage of different materials. A number of different methods as well as kinds of devices are used for dealing with these plied materials.

Stockyard Equipments - An Overview

The piles can consist of materials from 5,000 bunches to some million loads, while taking care of see post rate can differ from 100 loads per hour to 2,000 heaps per hour. The capability of the open stack storage space usually varies from 7 days to 45 days requirement of the consuming unit of the plant.

In open pile storage space different methods of piling (Fig 1) can be made use of. In the cone covering method, the stack is developed by depositing material in a single cone from a fixed position.

This procedure proceeds in the longitudinal instructions of the storage space stack up until the accumulation is complete. In the chevron method, the material is transferred by the stacker relocating to and fro over the centre line of the stack. However, the chevron piling approach triggers segregation of the material with great fragments in the main part of the heap as well as rugged particles on the surface area and at the end of the pile.

Everything about Logistics Companies Transportation

In the windrow approach, material is transferred from a number of settings across the full size of the stack. This method requires a luffing and slewing stacker. The windrow technique avoids segregation as well as makes certain a lot more even circulation of fine as well as crude bits throughout the pile. The windrow approach is favored in instances where the reclaimer is only running in one component of the pile sample each time or in cases where segregation makes an open heap base undesirable.Report this wiki page